A little history

THE OLDEST SOAP IN THE WORLD

Le véritable savon d'Alep ne peut être fabriqué en usine ou produit à grande échelle. Contrairement aux savons industriels qui envahissent le marché, sa fabrication repose sur un savoir-faire artisanal et une cuisson saisonnière respectant les traditions..

Depuis des générations, des familles syriennes perpétuent cet art et suivent un processus ancestral inchangé. Si ce savon a traversé les millénaires, c'est grâce à l'unicité de son terroir : la richesse de la terre, les conditions géographiques idéales, la qualité des ingrédients et la patience nécessaire à son élaboration. Autant d'éléments qui font du savon d'Alep un produit d'exception, authentique et intemporel.

Family know-how

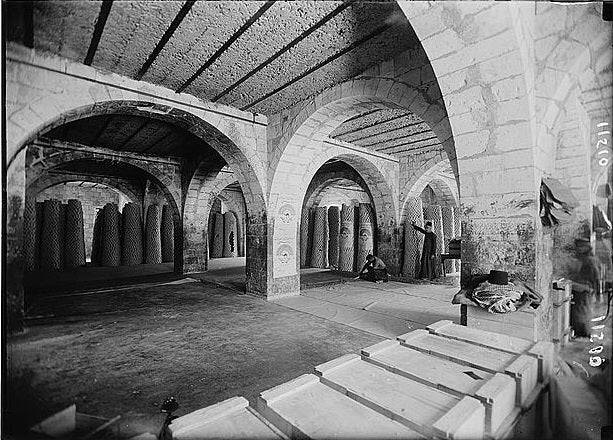

Authentic House

Aleppo soap contains only 4 ingredients. This does not mean that its manufacture remains simple. Its preparation requires knowledge to achieve a final result of excellence.

There are around ten companies that have mastered this know-how. Their role is essential and their commitment is a heavy responsibility. They must, while remaining honest, continue to produce the most beautiful things Aleppo has to offer to the world. The family name is indicated by the seal stamped on the face of the soap. Some houses stand out due to their reputation and age, such as the following families (non-exhaustive list).

Families producing Aleppo soap

Zanabili House “زنابيلي” (since ≈ 1870)

Maison Fansa “فنصة” (since ≈ 1848)

Jebeyli House “جبيلي” (since ≈ 1750)

Maison Fadel “فاضل” (since ≈ 1925)

Maison Sabouni “صابوني” (since ≈ 1975)

Maison Kadah “قداح” (since ≈ 1970)

Najjar House “نجار” (since ≈ 1895)

Maison Tahhan “طحان” (since ≈ 1925)

Manufacturing process

The Savon d'Or collection comes from these Syrian houses which have a reputation leaving no doubt about the quality of the soap.

Contrairement aux cosmétiques industriels fabriqués en continu, le savon d'Alep impose son propre tempo dicté par la nature. Tout commence en automne avec la récolte des olives, ingrédient essentiel à sa fabrication. L'hiver est consacré à la cuisson, permettant au savon de refroidir et de se solidifier. Puis, au fil des mois, le savon sèche lentement sous le soleil du printemps et de l'été, se transformant peu à peu : sa teinte verte éclatante évolue vers un brun doré. Un processus minutieux qui fait du savon d'Alep un produit unique, respectueux du temps et du savoir-faire ancestral.

La fabrication dure plusieurs jours, pour simplifier le processus, on distingue les grandes étapes suivantes:

1 – Pasting:

Olive oil, water and caustic soda are brought to the boil in huge cauldrons. The saponification of the olive oil begins. The latter takes a slimy form. The high temperature accelerates the reaction between the oil and the soda.

2- Release:

Saponification will generate soap and glycerin (following the decomposition of the olive oil). By adding salt water, we will wash the saponified paste to reduce the excess soda.

3 – Cooking:

We will restart the process of saponification of the olive oil with the remaining caustic soda until complete saponification.

4- Washing:

The creamy paste still contains too much soda at this stage. We will add water several times to reduce the soda content and refine the dough.

5 – Pouring:

After letting it rest, we will pour the dough onto a thin sheet directly onto the ground. The paste will dry until the next day where it will change from a liquid to a solid form.

6- Cutting & stamping:

With a blade rake, we cut the soap which is then stamped one by one with the seal of the producing family.

7 -Drying:

The soaps are then arranged in a way to promote the passage of air and provide optimal drying.

What makes Aleppo soap unique

Authenticity is achieved following compliance with these three conditions:

Condition 1: 4 ingredients only

Olive oil

– second-pressed olive oil ( Olea europaea L. ) (the first pressure is generally reserved for food use). It is the most abundant ingredient in Aleppo soap. Some manufacturers cheat by adding different oils, such as palm oil (much cheaper) and add odorants to hide the smell. (Picture 1)

Condition 1: 4 ingredients only

Laurel berry oil

Laurel berry oil (black fruit rich in fat), from ( Laurus Nobilis ), is extracted by distillation from the berry. The process boils down to boiling the berry in water, the fruit will release pulp which will be recovered to release its oil. (Picture 2)

Condition 1: 4 ingredients only

Sodium hydroxide

– Soda (sodium hydroxide) used to enable the hot saponification reaction. The latter is treated beforehand so that it becomes “ caustic ” soda.

Condition 1: 4 ingredients only

The water

Pure and mineral. No chemicals, additives or odorants should be added.

Condition 2:

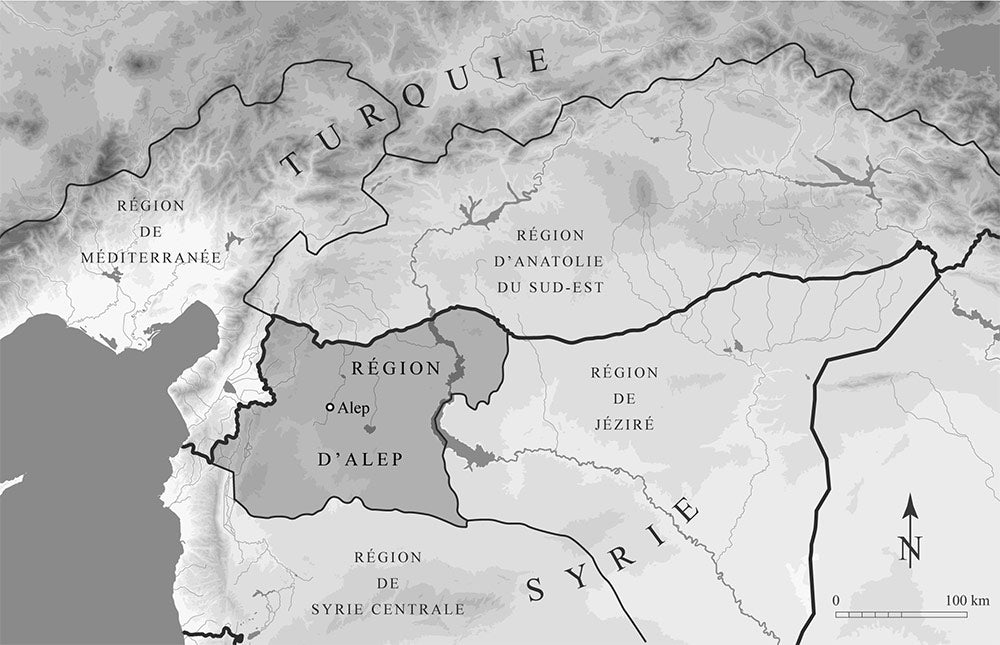

Geography

The Aleppo region is known for the fertility of its land, recognizable by its red color. It promotes agriculture focused on noble products such as olive oil, bay laurel oil and the famous Aleppo pistachio ( Pistacia voir ). The Mediterranean climate allows for the 4 very distinct seasons necessary for the making of this soap.

Condition 3:

Maturity

After manufacturing, the soap requires a minimum drying time (9 months) before any use. The soaps are stacked in such a way as to allow air to pass through and allow optimal drying.

When it dries, the soda used for the saponification reaction will decrease over time. Following its decomposition, the moisture content in the soap will decrease and dry out. The more mature the soap, the more it improves and brings out its qualities. It is a living soap that breathes; if it is poorly stored, humidity will slow down its drying. Likewise if the soap is packaged in plastic. It will not be in contact with air and therefore its drying slows down.

Chez SavondOr , nous ne sélectionnons que les meilleurs savons d'Alep, ceux qui respectent un savoir-faire ancestral et répondent aux critères les plus exigeants. Chacun de nos savons a été affiné pendant au moins 3 ans , garantissant une qualité optimale et une texture parfaitement sèche. Nous sommes fiers de proposer des savons rares, d'une maturité exceptionnelle pouvant atteindre 10 ans, comme notre précieuse fournée de 2014, aujourd'hui quasiment introuvable.

Notre ambition ? Devenir la référence du savon d'Alep haut de gamme , en mettant à l'honneur un produit d'exception, alliant tradition et prestige.